OUR PRODUCTS

Tap your full potential with our expertise in cylinders liners!

We develop and deliver grooved liners, structured liners, press-fit liners, hybrid liners and wet liners customized to precisely meet your requirements.

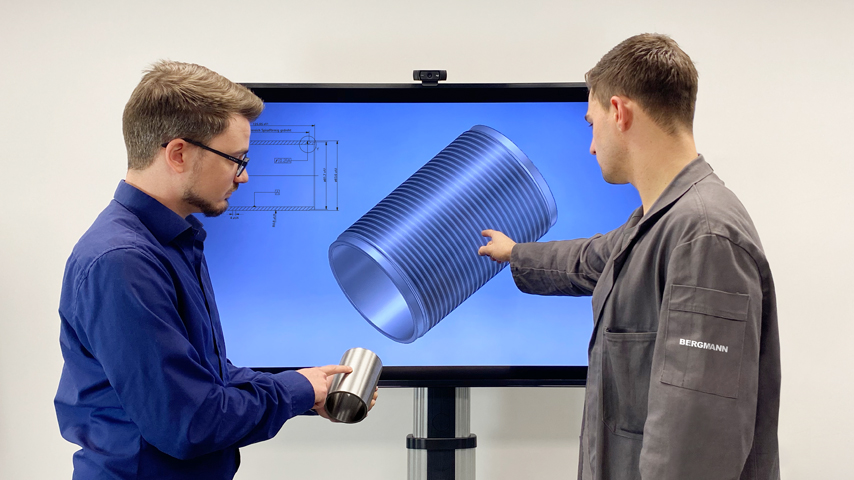

You know our name – discover our strengths! From the very first idea for you to the on-screen development and planning within an experienced team to scrupulous production and quality assurance – we are here for you.

Bergmann Automotive is your partner for cast liners of consistently high quality, which is certified and continuously inspected.

Our performance – your quality guarantee

Tap your full potential with our expertise in cylinders liners!

We develop and deliver grooved liners, structured liners, press-fit liners, hybrid liners and wet liners customized to precisely meet your requirements.

Tap your full potential with our expertise in cylinders liners!

We develop and deliver grooved liners, structured liners, press-fit liners, hybrid liners and wet liners customized to precisely meet your requirements.

Take the pressure off your development department: in the engine industry, you need first-rate products at the cutting edge of technology. We meet this demand through continuous research and development efforts to improve our products and processes. Bergmann Automotive employs experts who know what the market wants and whose expertise is the basis for trendsetting innovations.

We use secondary metals that have been meticulously sorted and processed on our premises as well as recycled circuit materials such as metal chips of a high quality as raw materials for our cast liners. We have been sourcing raw materials from reliable and certified raw material dealers for many years. The entire storage area is covered so that the materials stay dry.

More than 60 years of experience in smelting combined with the necessary metallurgical analyses ensure, among other things, unwavering casting quality at the highest level. By constantly adapting our processes to the latest technological advances, we ensure that the requirements of our customers are met both today and tomorrow.

With unique process expertise and fully automatic casting carousels, we manufacture tubes using a high-quality centrifugal casting process. The casting carousels were manufactured exclusively for us based on the requirements of Bergmann Automotive.

We have semi-automatic production capacities at our disposal for smaller batch sizes and prototypes for new production runs. The highest quality standards expected by our customers are also achieved in this area.

Following the casting process, the blanks are carefully processed on modern transfer machines or CNC-controlled production cells at Bergmann Automotive. It goes without saying that all customer specifications are taken into account and implemented. We design and build all processing machines ourselves in close cooperation with Bergmann Maschinenbau. Our plants are checked and maintained as a preventive measure by our own maintenance department.

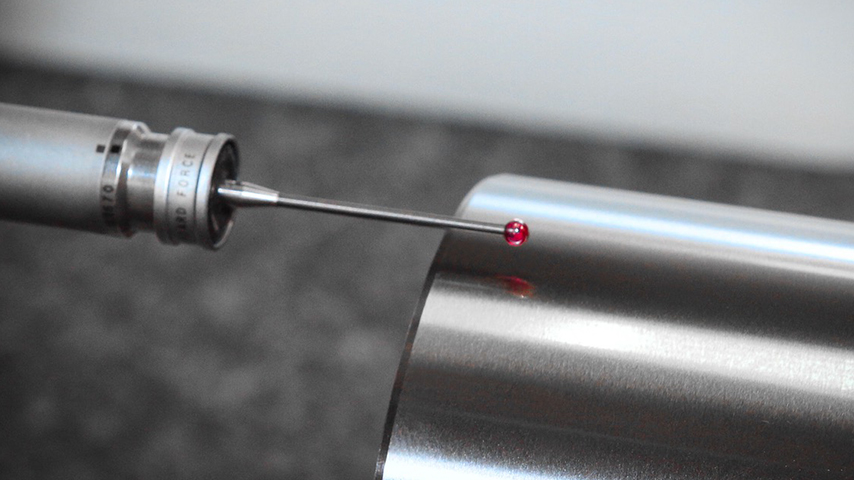

High quality and precise manufacturing are our top priorities. This is why continuous quality tests are carried out in our own laboratory, precision measuring room and our test station, using 3D measuring equipment to determine mechanical and technical or metallographic material characteristics, for example. Our laboratory is equipped with the necessary equipment for analyses relating to mass production, such as hardness testing or structure evaluation.

As a key supplier to international subcontractors and OEMs, Bergmann Automotive has already worked with almost all well-known automobile manufacturers. Your trust in our reliability drives us to achieve even more for you each and every day. Our name represents long-standing customer relationships that pay dividends for both parties over the long term.

As a key supplier to international subcontractors and OEMs, Bergmann Automotive has already worked with almost all well-known automobile manufacturers. Your trust in our reliability drives us to achieve even more for you each and every day. Our name represents long-standing customer relationships that pay dividends for both parties over the long term.

Bergmann Automotive GmbH

Gießereiweg 1

30890 Barsinghausen

Germany

(With satnav: Hannoversche Strasse 75, Barsinghausen)

We are happy to answer any question you may have with our full expertise and experience.